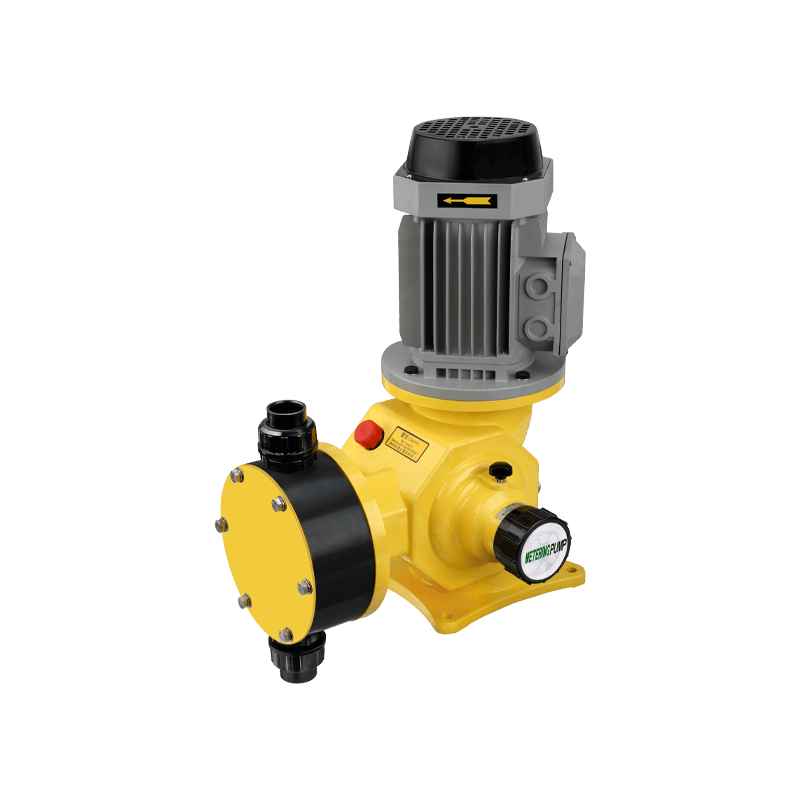

Are you looking for a reliable and versatile mechanical diaphragm metering pump to meet the needs of your business. With so many brands and varieties on the market, it can be difficult to identify which one is best suited for your unique requirements. To help make selecting the proper diaphragm pump easier, we’ve put together this informative guide breaking down everything you need to know about these pumps so that you can select with confidence. Read on to learn more!

1.Factors to Consider When Choosing a Diaphragm Metering Pump

When it comes to selecting a diaphragm metering pump, there are several factors to consider. The first thing you need to look at is the flow rate. You want to make sure the pump can handle the intended flow rate of your application, without causing any issues. Pump head materials is another important consideration. Different materials are suited for different processes, so make sure you select one that is compatible with your chemicals or fluids. Also, don't forget to consider the maximum operating pressure and temperature, as well as the accuracy level of the pump. By taking these factors into account, you can ensure that you select the best diaphragm metering pump for your needs, which will provide consistent and reliable performance.

2.Understanding Diaphragm Metering Pump Specifications and Performance Metrics

Diaphragm metering pumps are essential for precise and reliable liquid dosing in many industries, such as water treatment, chemical processing, and oil & gas. However, selecting an appropriate pump can be challenging due to the variety of specifications and performance metrics available. To ensure the pump meets your requirements, you need to understand parameters such as flow rate, pressure rating, suction lift, discharge head, viscosity, temperature range, and chemical compatibility. Moreover, you must consider factors that affect the pump's performance, such as diaphragm material, drive mechanism, stroke length, and frequency. By learning how to read and analyze diaphragm metering pump data sheets, you can save time, reduce costs, and improve productivity.

3.The Importance of Flow Rate and Pressure in Mechanical Diaphragm Metering Pump Selection

Mechanical diaphragm metering pumps are an essential tool in industrial processes, where precision and accuracy are paramount. When selecting a mechanical diaphragm metering pump, two crucial factors to consider are flow rate and pressure. The flow rate refers to how much fluid the pump can move over time, while the pressure is the force applied to the fluid to move it against resistance. These factors are key to ensuring precise and consistent dosing, which is crucial in applications such as water treatment and chemical processing. In addition, selecting the right pump based on flow rate and pressure can help ensure the durability and longevity of the equipment. Understanding the importance of flow rate and pressure in the selection of a mechanical diaphragm metering pump is essential to achieving optimal performance in any industrial process.

In summary, the selection of a diaphragm metering pump is a complex process that requires careful consideration. There are numerous factors to keep in mind, ranging from pump specifications and performance metrics to flow rate and pressure. As you progress through the selection process, it may be helpful to consult with experts to make sure all your questions are answered and you find the best solution for your specific application. Additionally, make sure to keep track of the regulations that apply to your particular sector, as it is vital to maintain compliance when selecting a diaphragm metering pump. Choosing the right diaphragm metering pump can ensure that your operations run smoothly and efficiently and point you towards success. If you need professional assistance along the way, reach out to experts!